Aluminium Foil Machine

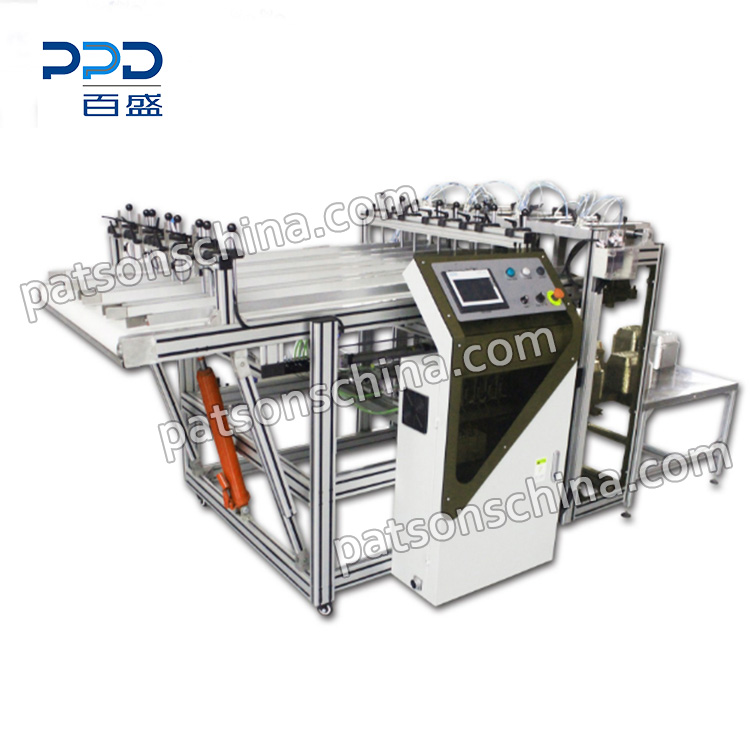

Automatic safety covered aluminium foil backing furnace pad production line

-

PPD-ABP63

-

Automatic safety covered aluminium foil backing furnace pad production line is new designed model to produce the kitchen use aluminium foil backing furnace pad,anti oil pad for gas cooker,aluminium foil container etc..

Full production line is included feeding machine,high accuracy press machine,automatic stacker,collection.

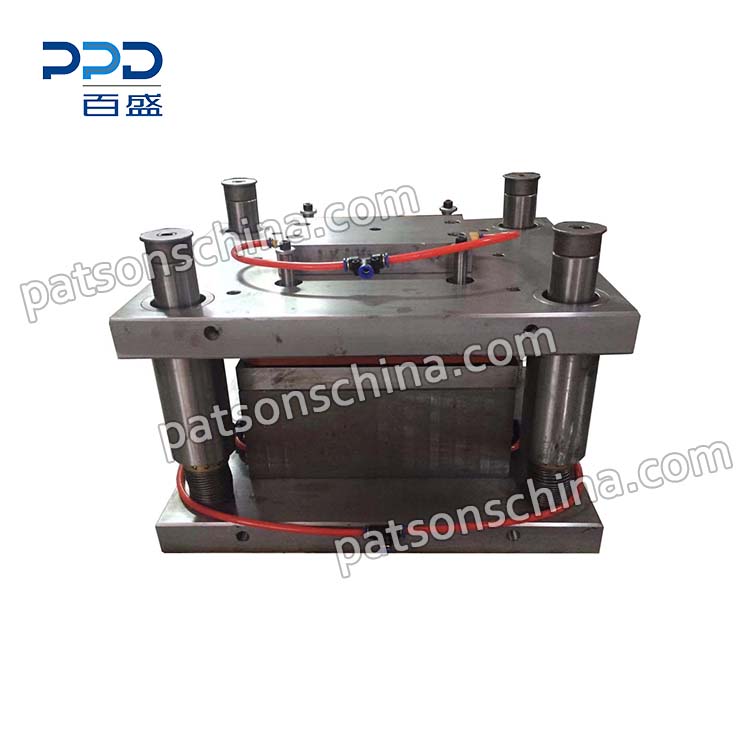

By changing the different size of mould,can make the products as buyer requirement.

With the safety cover,machine production process is safer and reduces production safety accidents

Video

Fearures:

1:It possess feature like momory control,complete automatic,smooth running,easy to operate.

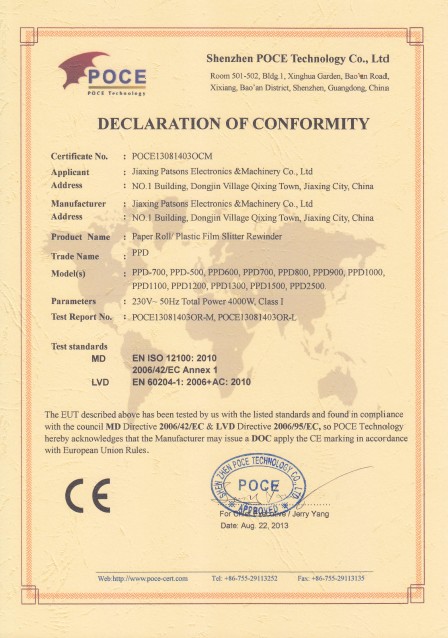

2:It has passed CE certificate,with the safety cover,machine production process is safer and reduces production safety accidents

3:Aluminum Foil Feeding Machine

Feeding machine design reasonable and stable,good performance for small thickness ad big width material,without wrinkle happen under higher speed running

4:Safety covered H-type press

Steel Plate Wielded Machine body marked with high rigidity and less deformation.

Crankshaft is arranged in longitudinal direction, which has well-designed structure and beautiful appearance.

The sliding block adopts hexagonal extended guide rails with high precision, and double pneumatic balance sliding block of high precision is used.

It adopts combined pneumatic friction clutch and barking device to ensure steady clutching, low noise level, and flexible action.

It has steel press-down type safety device with simple structure and safe performance.

The imported PLC electronic control system and Duplex safety valve are used to achieve emergent stop, inching, sing action and continuous operation. Electric adjustment of mould load height is adopted, enabling easy operation.

5.Auto stacker

Auto stacker is necessary key part to achieve for complete automatic aluminium foil container production line.

We have lane number from 1 to 5 lanes for different mould production.

Special size can be customized as costomer requirement.

6.Scrap Collecting Device

It is using for collecting the scrap in the production time, avoid that products are not able to be blown out in case some scrap are left in the Mould. It can significantly reduce the labor intensity, Improve working efficiency, and make sure the cleaning of workshop and efficient production

Machine data:

1.Raw material: Aluminum foil; Thickness: 0.030mm ~0.250mm

Alloy: 8011,8006,3003,3005; Temper O to H24;

2.Max width of Aluminum foil:800mm(as buyer requirement)

3.Max outer diameter of Aluminum foil:700mm

4.Inner core diameter of Aluminum foil:76mm/152mm

5.Running speed:40-68 times/min

6.Cavity:Multi-cavities or one cavity

7.Air supply: 0.5- 0.8 Mpa,0.3m3/min

8.Machine dimension: 6000*2600*3300mm

NOTE:Mould size is customized as customer requirement

Related Product

Since 1987, Jiaxing Patsons Machinery Co Ltd is focused on different packaging machinery, and packaging material converting machinery etc. Through continuous efforts, we have been the professional in the research & production of stretch film machine, cling film machine, aluminium foil machine, alcohol pad machine, wet wipes machine, paper roll slitter rewinder, paper processing machinery, printing machinery and all kinds of customized packaging material converting machinery.

FAQ

#Feedback: Automatic safety covered aluminium foil backing furnace pad production line

Send Inquiry by feedback form learn more about product detail, price, etc. Your email address will not be published. Required fields are marked *