Slitting&Rewinding Machine

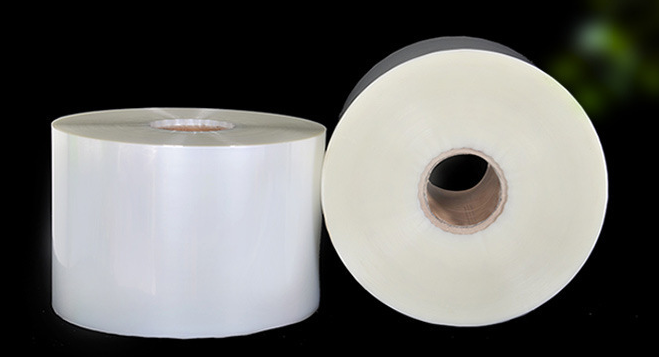

PP Plastic Roll Slitter Rewinder

-

PPD-SR1100

-

PP plastic roll slitter rewinder is suitable for longitudinal slitting of various roll-shaped materials such as PP plastic roll,paper,copper foil and composite plastic paper etc.

PP plastic roll slitter rewinder has a photoelectric tracking correction system, the tension of rewinding and unwinding is controlled by a magnetic powder clutch,and the host adopts frequency conversion speed regulation.

The slitting width can be adjusted according to requirements.The slitting is accurate,the slitting speed is fast,and the operation and maintenance are convenient.

Video

Features:

1:It has automatic stop for meter counting and automatic speed regulation for line speed.

2:Unwinding tension is controlled by magnetic powder clutch,rewinding tension is magnetic powder clutch is adopted,and the main machine drives the magnetic powder to manually control.

3:Use air shaft rewinding,stable.

4:Multi-function model,our this model is suitable for different materials,such as pp plastic roll,nonwoven fabrics,composite,paper etc..

Machine data:

Machine name:PP Plastic Roll Slitter Rewinder

Machine model:PPD-SR1100

Material:PP plastic roll,plastic film,paper etc.

Unwind roll width:1100mm

Unwind roll ID:76mm

Unwind roll OD:600mm max

Finished roll width:25-1100mm max

Finished roll ID:76mm

Finished roll OD:450mm option

Design speed:160m/minute(deponds on raw material)

NOTE:Special size can be customized as buyer requirement.

Related Product

BOPP Adhesive Tape Slitting Machine

PPD-BO1280

Medical tape slitter rewinder

PPD-MTSR1100

Bopp opp adhesive tape slitter machine with cover

PPD-BOPP1600

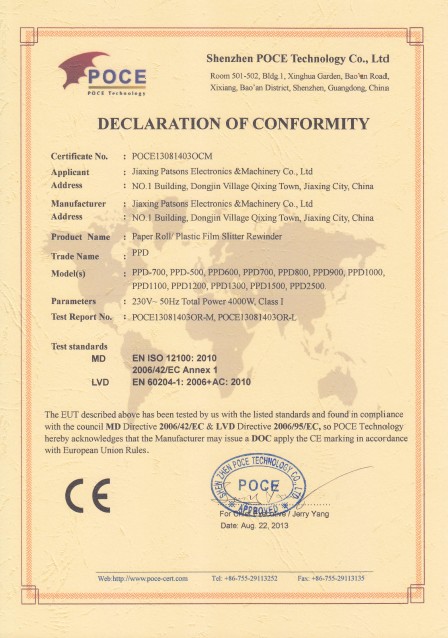

Since 1987, Jiaxing Patsons Machinery Co Ltd is focused on different packaging machinery, and packaging material converting machinery etc. Through continuous efforts, we have been the professional in the research & production of stretch film machine, cling film machine, aluminium foil machine, alcohol pad machine, wet wipes machine, paper roll slitter rewinder, paper processing machinery, printing machinery and all kinds of customized packaging material converting machinery.

FAQ

#Feedback: PP Plastic Roll Slitter Rewinder

Send Inquiry by feedback form learn more about product detail, price, etc. Your email address will not be published. Required fields are marked *