Food Paper Rewinder

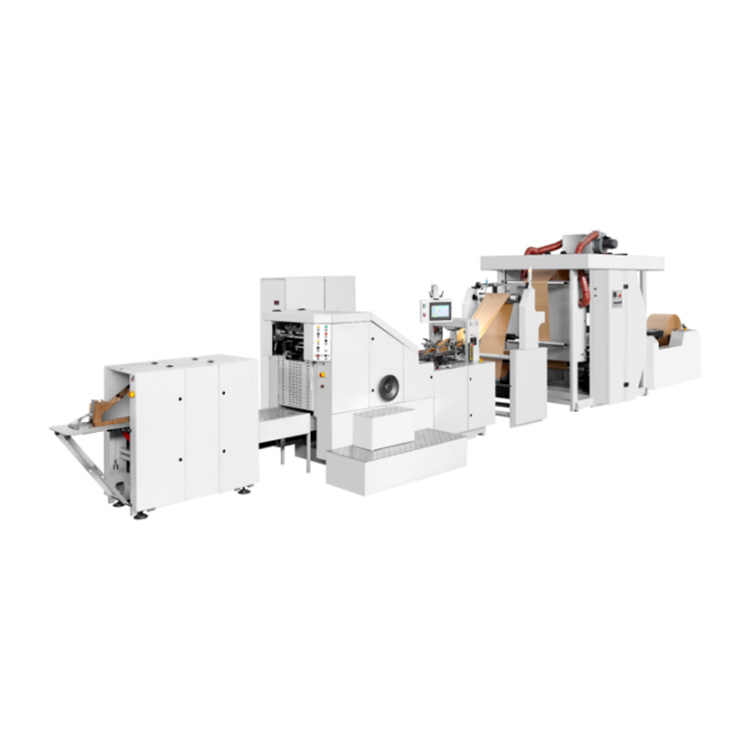

Roll feeding square bottom paper bag machine with 4 colors printing machine

-

PPD-PBM190

-

Rolling feed square bottom paper bag making machine, it uses paper roll in blank or printed as raw material. consists of automatic center forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time,The machine is more convenient, more efficient, more stable, can produce a variety of different paper bags, leisure food bags, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

Video

Features:

1.Adopt France/SCHNEIDER touch screen human-computer interface, operate and control easily.

2.Adopt Germany original REXROTH PC control, Integrated with optical fiber, ensure high speed running steadily.

3.Germany original REXROTH servo motor and German original SICK Photoelectric eye correction, tracking printing bag accurately.

3.Germany original REXROTH servo motor and German original SICK Photoelectric eye correction, tracking printing bag accurately.

4.Raw material load adopt pneumatic cylinder up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt italy SELECTRA, reduce adjustment time.

The main features of flexo printing:

1.The ink is transported by a separate gear motor, and the ink pump circulates the ink.

2.Use a closed scraper to scrape ink, ensure high-speed printing and prevent ink splash

3.Pneumatic lift and drop mode, automatically start after shutdown, automatically transport ink after printing plate installation,Printing plate automatic printing after booting

4.Independent closed type hot and cold dual function drying system

Machine data:

Machine name:Roll feeding square bottom paper bag machine with 4 colors printing machine

Machine model:PPD-PBM190

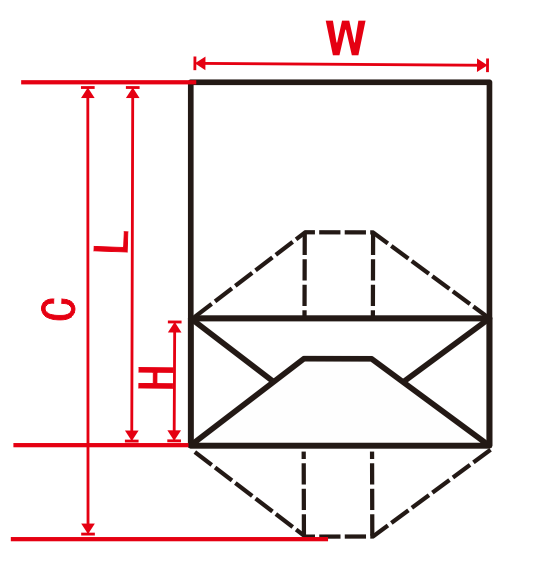

Paper bag length:190-370mm

Printing paper bag lengt:190-360mm.

Paper bag width:80-190mm

Paper bag bottom width:50-105mm

Paper thickness:50-130g/㎡

Machine Speed:30-260pcs/min

Paper bag speed:30-200pcs/min

Paper roll width :290-620mm

Roll paper diameter:Φ1500mm

Inner diameter of paper:Φ76mm

Printing area

Printing width:100-760mm

Printing length:230-500mm(190-230mm Two bags in one version)

Printing speed:5-86m/min

Color accuracy:≤±0.20mm

Plate thickness(Including the thickness of the double-sided tape):2.28mm+0.38mm

Working Air Current :More than 0.36m³/ minutes, 0.5-0.8 MPa

Machine power :380V,3phase,4wire,22.9KW

Total weight:8400kg

NOTE: ANY SPECIFICATIONS AND BE CUSTOMIZED AS BUYER REQUIREMENT.

|  |

Related Product

Automatic parchment paper slitter rewinder

PPD-PPSR450

Since 1987, Jiaxing Patsons Machinery Co Ltd is focused on different packaging machinery, and packaging material converting machinery etc. Through continuous efforts, we have been the professional in the research & production of stretch film machine, cling film machine, aluminium foil machine, alcohol pad machine, wet wipes machine, paper roll slitter rewinder, paper processing machinery, printing machinery and all kinds of customized packaging material converting machinery.

FAQ

#Feedback: Roll feeding square bottom paper bag machine with 4 colors printing machine

Send Inquiry by feedback form learn more about product detail, price, etc. Your email address will not be published. Required fields are marked *