Medical surgical face mask generally have a three-layer (non-woven) structure,three layers of medical surgical face mask decomposition: the outer layer has anti-foam design (spunbond non-woven fabric) + middle filter (meltblown non-woven fabric) + inner layer moisture absorption (spunbond non-woven fabric).

Meltblown cloth is mainly made of polypropylene, and the fiber diameter can reach 1 ~ 5 microns. There are many voids, fluffy structure, and good anti-wrinkle ability. These ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the meltblown cloth has good filterability, shielding, heat insulation and oil absorption.Can be used in the fields of air, liquid filter materials, insulation materials, absorbent materials, mask materials, thermal insulation materials, oil-absorbing materials, and wiping cloths.

The meltblown nonwoven is widly used in medical and health cloths:surgical gowns,protective clothing, disinfection cloths,masks,diapers,women's sanitary napkins etc..

Meltblown nonwoven specifications:

Gram weight: 18g-500g

Width: generally 160cm and 180cm (can also be determined according to customer needs)

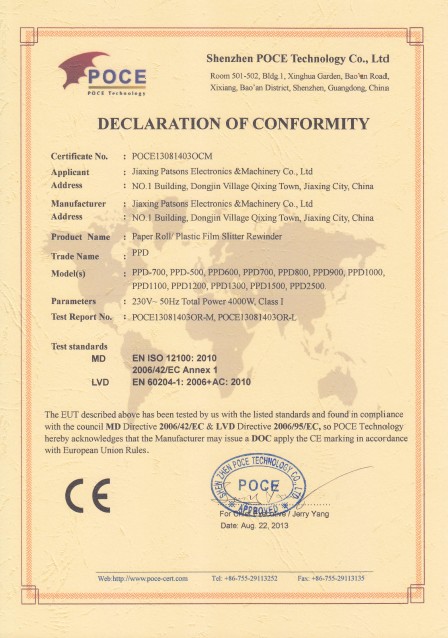

Our nonwoven slitter rewinder is professional model to slit and rewind the raw material nonwoven(such as meltblown nonwoven) to the standard production rolls.

The small roll width can be 15cm,30cm as buyer requirement.

Welcome to visit our factory and buy machines.

We also have different kinds of medical equipments,such as alcohol swab packaging machines,face mask production machine and face mask packaging machine etc..