Automatic Packaging Line

Automatic table cover rewinding machine

-

PPD-TCR15

-

Automatic table cover rewinding machine is our new model of table cover rewinding machine.It is an industry-specific machine and equipment used to replace the traditional manual folding of plastic products.Rotational power is generated by electric and pneumatic means to achieve automatic folding effect, instead of frequent manual folding actions.

The biggest advantage of this mode of automatic folding machine is its flexibility and high efficiency. Several actions from automatic reclaiming-folding-cutting-unloading-discharging are combined at one time. It only takes 4.5 seconds and the product tolerance is within 5mm.In today's era of rapid product upgrades,it can greatly save investment in fixed assets.

Video

Features:

1.Using a special feeder to automatically transport the plastic film to the designated position

2.The friendly man-machine interface allows you to easily complete the program settings

3.Improve work efficiency and productivity, improve staff work intensity

4.Can cooperate with production conveyor belt to realize automatic operation

5.Simple and convenient operation, high speed and precision

Machine data:

Machine name:Automatic table cover rewinding machine

Machine model:PPD-TCR15

Raw material:PE, PEVA, EVA and other plastic film products, disposable plastic tablecover (tablecloths)

Product width:max 420mm

Speed:4.5 seconds/piece

Voltage:220v,50Hz (option)

NOTE:ANY SPECIFICAITONS CAN BE CUSTOMIZED AS BUYER REQUIREMENT.

Related Product

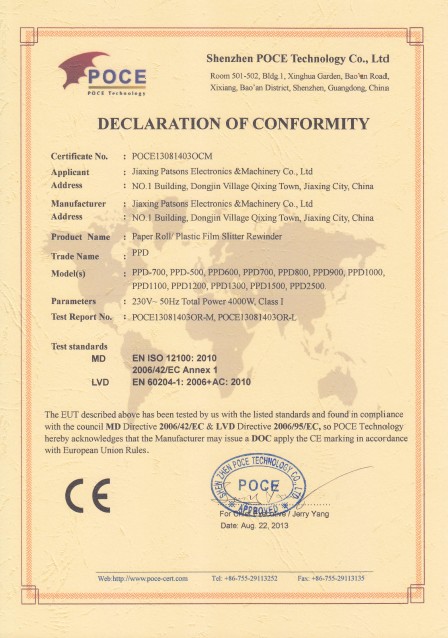

Since 1987, Jiaxing Patsons Machinery Co Ltd is focused on different packaging machinery, and packaging material converting machinery etc. Through continuous efforts, we have been the professional in the research & production of stretch film machine, cling film machine, aluminium foil machine, alcohol pad machine, wet wipes machine, paper roll slitter rewinder, paper processing machinery, printing machinery and all kinds of customized packaging material converting machinery.

FAQ

#Feedback: Automatic table cover rewinding machine

Send Inquiry by feedback form learn more about product detail, price, etc. Your email address will not be published. Required fields are marked *