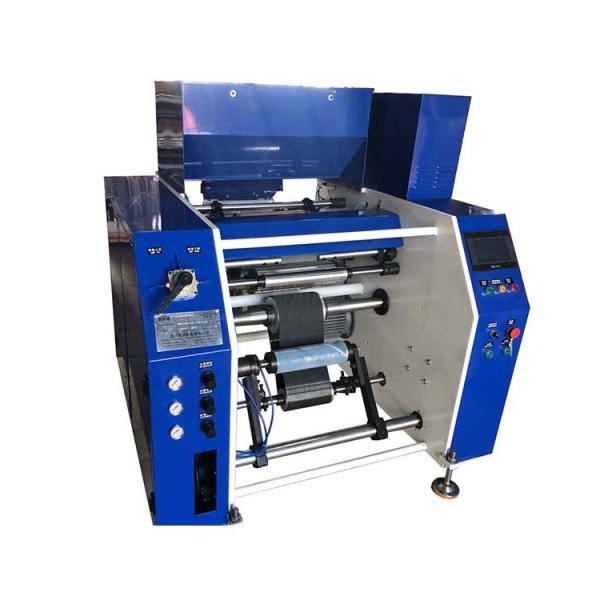

Cling Film Rewinder

Automatic single station cling film rewinder with safety cover

-

PPD-ACRSC450

-

Automatic single station cling film rewinder with safety cover is a machine customized by our company based on the actual requirements of customers on the basis of the automatic single station cling film rewinding machine. Wearing a safety cover can effectively reduce the noise during machine production and also better comply with EU production standards. The safety cover can be lifted and lowered, making it simple and convenient.

Automatic single station cling film rewinder with safety cover is an ideal choice for producing rolls of different width and different length cling film rolls.

Video

Features:

1: Switching paper tubes, rewinding,automatic transfer of finished products to the conveyor belt.

2: The human-machine interface is simple,set product roll meters and machine speed is easy.

3: Safe cover,adjustable for lifting and safety convenience.

Machine data:

Machine name:Automatic single station cling film rewinder with safety cover

Machine model:PPD-ACRSC450

Width of parent roll:300-450mm

ID of parent roll:3inch(76mm)

OD of parent roll:max 400mm

Width of baby roll:300-450mm

ID of baby roll:25/30/35/38mm(option)

Length of baby roll:600meters(option)

Machine speed:max 900meters/min

Voltage:220/380/415v,3ph

NOTE: ANY SPECIFICATIONS AND BE CUSTOMIZED AS BUYER REQUIREMENT.

Related Product

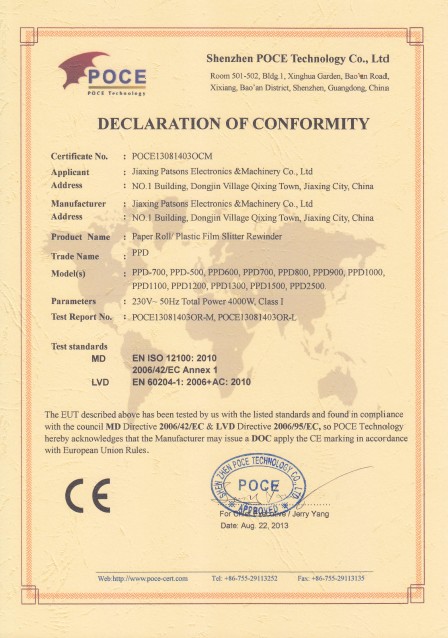

Since 1987, Jiaxing Patsons Machinery Co Ltd is focused on different packaging machinery, and packaging material converting machinery etc. Through continuous efforts, we have been the professional in the research & production of stretch film machine, cling film machine, aluminium foil machine, alcohol pad machine, wet wipes machine, paper roll slitter rewinder, paper processing machinery, printing machinery and all kinds of customized packaging material converting machinery.

FAQ

#Feedback: Automatic single station cling film rewinder with safety cover

Send Inquiry by feedback form learn more about product detail, price, etc. Your email address will not be published. Required fields are marked *