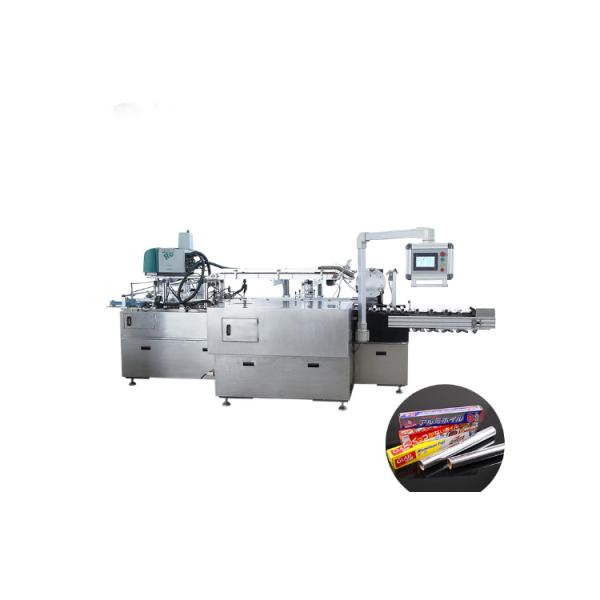

Automatic Packaging Line

Semi automatic face mask production line

-

PPD-SAFM

-

Semi automatic face mask production line is included the face mask blank making machine and Face mask ultrasonic welding machine and earloop cutting machine.

1:Face mask blank making machine

Specifications:

1. The mask output is output by the conveyor belt, the speed is adjustable, the output is neat, the product quality is stable, the operation is convenient, and the production efficiency is high, up to 120-150 tablets per minute.

2. All-aluminum profile machine is neat and beautiful, no welding, no painting. Human-machine interface touch screen control, built-in time, total output, same-day output, set number of automatic alarm and shutdown, digital keys to adjust the filming speed.

3. The motor adopts a three-phase gear motor, the magnetic wheel deceleration with braking function, and the noise is extremely low.

4. All the masks are formed by ultrasonic welding, with superior performance and high-speed filming.

Technical data:

Speed: 120-150pcs/min

Machine weight: 650kg

Voltage: 220v

Power: 3.5kw

Host size: 2000*600*1200mm

Loading rack size: 1500*650*1400mm

Conveyor size: 1700*250*900mm

2:Face mask ultrasonic welding machine

Specifications:

Face mask ultrasonic welding machine is a high-precision welding machine of the ultrasonic series. It can weld non-woven masks firmly. Ultrasonic mask spot welder welding effect is better than ordinary mechanical effects. It is clean and beautiful, and it is an indispensable tool for production and processing manufacturers.

This machine is operated by a single person. This machine uses ultrasonic waves to dissolve the elastic band on both sides of the mask body to complete the finished product of the elastic band mask. The foot switch can be finished. Cylinder welding fastness, adjustable welding time, built-in time relay, adjustable air pressure, moderate current adjustment, no noise, and extremely easy operation.

1. The ultrasonic power is strong, up to 1500W, and it has large, medium, and small power adjustment functions to meet the welding requirements of different materials and thicknesses;

2. Multi-channel ultra sound protection system to ensure the safe and stable operation of the main machine; 3. The bottom mold rotation function makes the chassis wear uniform, prolongs the service life and improves the processing quality; (lace machine)

4. This machine uses manual welding of rubber bands, which is easy to operate. This model can preset welding time according to different thickness materials to avoid manual control of welding, which results in short and unsteady time and excessive welding time. Disadvantages such as broken fabrics.

Technical data:

Speed: 20-30pcs/min

Machine weight: 100kg

Voltage: 220v

Power: 2.3kw

Host size: 1000*800*1200mm

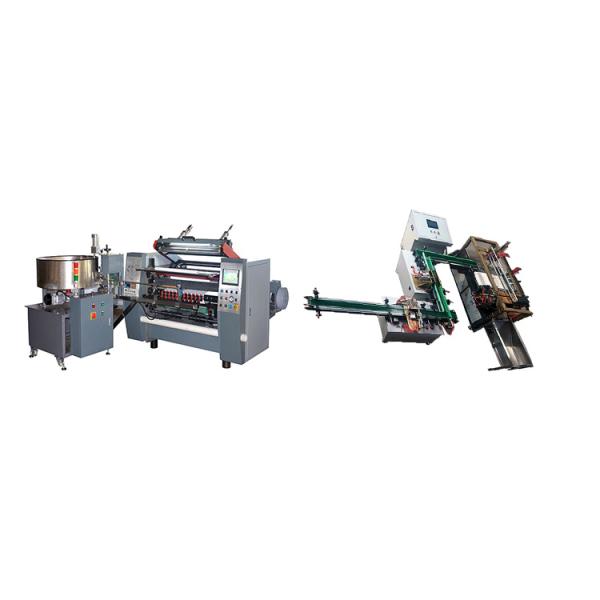

3:Earloop cutting machine

Specifications:

Earloop cutting machine is cut the earloop jumbo roll into product earloop. When customers buy earloop, the earloop are rolled and rolled into rolls.

When using a manual spot welder,you need to use each earloop.

So you need equipment to cut the earloop into pieces. You need a earloop cutting machine.

Technical data:

Speed: 30 pcs/min

Machine weight: 70kg

Voltage: 220v

Power: 1.5kw

Host size: 1200*540*1200mm

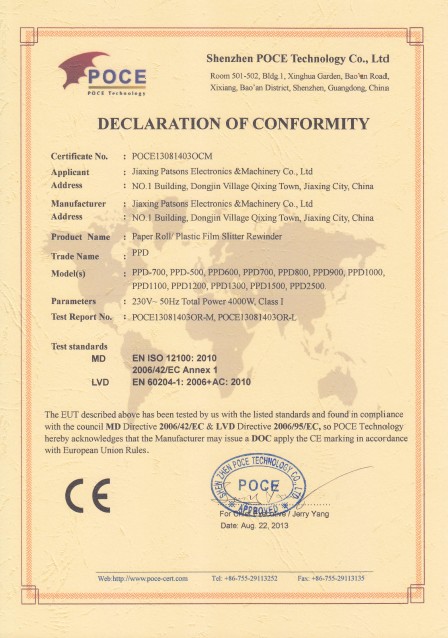

Since 1987, Jiaxing Patsons Machinery Co Ltd is focused on different packaging machinery, and packaging material converting machinery etc. Through continuous efforts, we have been the professional in the research & production of stretch film machine, cling film machine, aluminium foil machine, alcohol pad machine, wet wipes machine, paper roll slitter rewinder, paper processing machinery, printing machinery and all kinds of customized packaging material converting machinery.

FAQ

#Feedback: Semi automatic face mask production line

Send Inquiry by feedback form learn more about product detail, price, etc. Your email address will not be published. Required fields are marked *